Understanding Precision Die Cutting

Precision die cutting is a manufacturing process that allows the production of intricate shapes and components through controlled cutting of various materials. This technique has found widespread use in industries ranging from packaging and textiles to electronics and medical devices. The efficiency and accuracy of precision die cutting make it a popular choice for companies looking to create custom parts efficiently. For an in-depth look into the various applications and benefits, you can explore precision die cutting.

What is Precision Die Cutting?

At its core, precision die cutting involves the use of a sharp metal blade (the die) to cut through materials such as paper, plastics, foam, and metals into specified shapes or designs. Unlike traditional cutting methods, which may be less precise and slower, precision die cutting uses precisely engineered dies to ensure uniformity, exactness, and speed.

The process typically begins with the creation of a die made from hardened steel, specifically tailored to the design requirements. This die is then mounted on a press that slices through the chosen material with consistent pressure. The result is a cleanly cut shape that adheres closely to predetermined specifications, often within tight tolerances.

Applications in Various Industries

Precision die cutting serves a multitude of industries, leveraging its speed and accuracy to meet complex manufacturing demands. Here are a few notable applications:

- Packaging: Companies frequently utilize precision die cutting to produce custom packaging solutions designed for specific products, ensuring a perfect fit that enhances protection and aesthetics.

- Automotive: In the automotive industry, it is used to create specialized gaskets and seals that require a high level of precision to maintain efficiency and performance.

- Medical Devices: Medical industry applications include the production of sterilization pouches, bandages, and other disposable items that meet stringent regulatory standards.

- Electronics: Precision die cutting is employed to manufacture insulation components, circuit boards, and various electronic protective elements with exact specifications.

Key Benefits of Precision Die Cutting

The advantages of precision die cutting extend beyond simple shape creation, encapsulating various aspects of production:

- Efficiency: The process enables mass production of parts, significantly reducing manufacturing time compared to manual methods.

- Accuracy: The use of custom dies results in exact dimensions and uniformity across all produced items, essential for applications requiring high precision.

- Material Versatility: Precision die cutting can be applied to a diverse range of materials, including but not limited to paper, cardboard, plastics, and metals.

- Cost-Effectiveness: While the initial cost of creating a die may be high, the long-term savings through reduced material waste and labor make it a financially viable option for many businesses.

Techniques and Methods

Flatbed vs. Rotary Die Cutting

Two primary techniques of precision die cutting are flatbed and rotary die cutting, each serving different needs based on the production requirements.

Flatbed Die Cutting

This method utilizes a flatbed press, where the die is pressed down through the material to create the desired shape. It is particularly effective for thicker materials and more complex shapes. Flatbed die cutting is commonly used when producing items such as cardboard boxes or intricate display units, allowing for higher cutting pressure and detailed designs.

Rotary Die Cutting

On the other hand, rotary die cutting involves the use of a cylindrical die that rotates, allowing for continuous feeding of the material. This method is ideal for high-volume production runs, particularly with flexible materials such as films and adhesives. Rotary die cutting typically offers faster production speeds and lower per-unit costs when working with long runs.

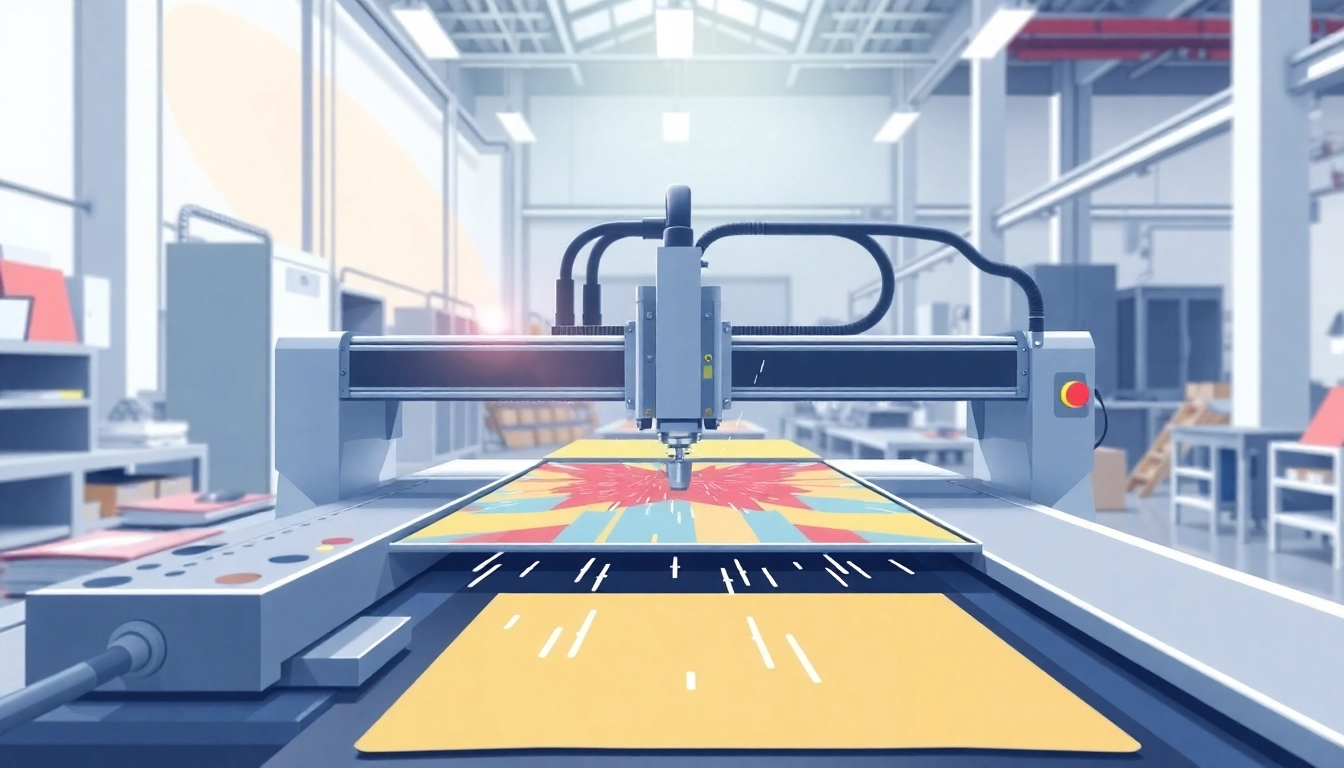

Laser Die Cutting: Advantages and Use Cases

Laser die cutting represents a newer technology in the die cutting space, employing focused laser beams to vaporize material into desired shapes. This technique boasts several advantages:

- High Precision: Laser cutting achieves higher precision and detail than traditional methods, making it suitable for intricate designs and complex geometries.

- No Tooling Costs: Since there is no physical die required, initial setup costs are significantly lower, especially for small batch productions.

- Material Diversity: Laser cutting can accommodate a broader range of materials, including thin metals, plastics, and fabrics, further expanding its applicability.

Laser die cutting is often favored in industries involving lightweight materials, such as textile manufacturing and electronics, where intricate shapes are crucial for functionality and aesthetics.

Common Materials for Precision Die Cutting

The versatility of precision die cutting is underpinned by the variety of materials that can be employed, including:

- Cardboard and Paper: Ideal for packaging and promotional materials.

- Plastics: Accommodates flexible and rigid components for various applications.

- Foams: Utilized in automotive and medical sectors for cushioning and insulation.

- Metals: Thinner gauges are often die-cut for automotive and industrial parts.

Choosing the Right Die Cutting Service

How to Evaluate Service Providers

Selecting a reliable die cutting service provider is crucial to ensuring quality and efficiency in production. Consider the following factors when evaluating potential partners:

- Experience: Look for companies with a solid track record and experience in your specific industry.

- Technical Capabilities: Ensure that they possess the necessary machinery and technology to meet precision requirements.

- Quality Assurance: Evaluate their quality control measures and whether they adhere to international standards.

- Customer References: Request references or testimonials from their past clients to assess reliability and service quality.

Questions to Ask Before Committing

Before finalizing a partnership with a die cutting service provider, ask the following questions:

- What is your lead time for sample production and full orders?

- What are your minimum order quantities?

- Can you provide design assistance if needed?

- What are your policies regarding changes or cancellations to orders?

Understanding Pricing and Cost Factors

The cost of precision die cutting can vary based on several factors:

- Material Type: Different materials may incur varied costs based on availability and processing requirements.

- Complexity of Design: Intricate designs requiring highly specialized dies will generally cost more.

- Volume: Larger production runs usually decrease the per-unit cost, making economies of scale a consideration.

Quality Assurance in Die Cutting

Importance of Tolerances in Die Cutting

In precision die cutting, tolerances are critical as they determine the acceptable limits of variation in the dimensions of the finished parts. Maintaining tight tolerances ensures that components fit and function as intended, especially in applications like automotive and medical devices, where precision is paramount. Typical tolerances range from +/- 0.001 inches to +/- 0.005 inches, depending on the material and process used.

Implementing Quality Control Measures

To ensure consistent quality, effective quality control measures should be implemented, including:

- Regular inspections of die cuts throughout the production process.

- Utilizing advanced measuring technology such as calipers and laser measurement systems for accuracy.

- Creating a feedback loop allowing personnel to report any anomalies for immediate resolutions.

Case Studies of High-Quality Projects

Real-world examples can illustrate the value of quality assurance in die cutting. For instance, a medical device company partnered with a precision die cutting service to produce surgical masks with exact specifications to ensure patient safety and comfort. Through regular quality checks, they maintained compliance with industry regulations while achieving a significant reduction in production time and material waste.

Future of Precision Die Cutting

Technological Innovations in Die Cutting

As industries evolve, so does technology in precision die cutting. Emerging innovations include:

- Automation: The integration of robots in die cutting processes is enhancing efficiency and reducing human error.

- Advanced Software: CAD/CAM systems streamline design and production, allowing for quick adjustments to meet client needs.

Sustainable Practices in Die Cutting

Sustainability has become a priority for many organizations. Die cutting services are adopting eco-friendly practices such as:

- Utilizing recyclable materials for die cuts.

- Implementing waste-reduction programs during production.

- Exploring environmentally friendly cutting fluid options in the process.

Trends Influencing the Industry

The precision die cutting landscape is shaped by various trends, including a growing demand for customization and rapid prototyping, the increased use of smart manufacturing practices, and a rising focus on ergonomic designs in consumer products. Companies that stay attuned to these trends will be better positioned to thrive in the competitive manufacturing arena.